- Product

Product Details

US150 Fire Barrier Foam

- Model:US150 Fire Barrier Foam

Product Introduction

Description:

Fire Barrier Foam is a two component flexible product, consisting of separate A and B liquid

components which, when mixed, forms a medium-density fire retardant foam.

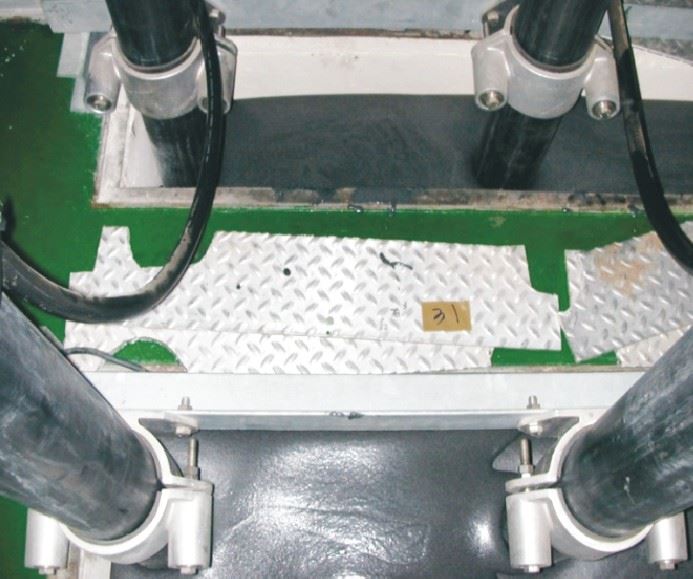

US150 / US110 is designed to seal large openings and multiple penetration areas such

as cablebundles, cable trays and metallic pipes.

Prior to foaming, the liquid components remain fluid allowing effortless sealing of any size and

shape opening.

After exposure to 1x10⁶ Gy (1x10⁸ rad) of neutron orgamma radiation, US150 &US110

will maintain full firestop performance characteristics 50 plus years.

Uses:

US150 / US110 Fire Barrier Foam seals single or multiple penetrations through concrete or

masonry floor slabs, walls and other fire-rated building partitions and assemblies.

Feature:

●Liquid properties conform to any size or shape

opening

●Proprietary intumescent properties

●Unparalleled resistance to fire

●consumption

●Halogen free

●Asbestos free

●Durable and maintenance free

Test:

●UL1479 2hr T Rating and F Rating

●FM approved

●ULC S115 2hrs FH Rating

●CNS14514, 3hrs, Class A and B

●GB23864

●ASTM E84

●ASTM E662

Installation:

Packing MAterial

Use at least 1 in. thickness of min 15 pcf ceramic fiber board firmly friction fitted into

opening as a permanent form and located flush withthe bottom surface of floor to

prevent fill material leakage.

Sealing

Generous application of sealant (INCA fire barrier silicone sealant

INSS2460 or caulk INSS1440),to be applied around the penetrant and the edges of

the opening,flush with the bottom surface of the floor to prevent fill material leakage.

Foaming

Min 7in. thickness of fill material applied within the annulus,flush with top surface

of floor.Two parts foam shall be mixed in accordance with the installation instructions

provided with the product.

Specification:

|

Model

|

US150

|

US110

|

|

Part A

|

Part B

|

Part A

|

Part B

|

|

Color

|

Black

|

Yellowish

|

charcoal gray

|

brown

|

|

Packing

|

14Kg / Pail

|

6Kg / Pail

|

20Kg / Pail

|

20Kg / Pail

|

|

Mixing ratio (by weight)

|

A:B = 7:3

|

A:B = 7:4

|

|

Foaming time

|

1 ~ 5 min.

|

1 ~ 5 min.

|

|

Optimum foaming temp.

|

20℃ ~ 30℃

|

20℃ ~ 30℃

|

|

Time for full cure

|

24 Hours

|

24 Hours

|

|

Foam rate

|

Approx. 2.5 ~ 4 times

|

Approx. 5 ~ 7 times

|

|

L.O.I.

|

≧32

|

≧32

|

|

Storage temp.

|

15 ~ 25℃

|

15 ~ 25℃

|

|

Combustion expansion rate

|

4 ~ 10 times

|

2 ~ 5 times

|